The phenomenon of starch retrogradation, commonly known as staling, presents a significant challenge in the food industry, particularly in baked goods and other starch-based products. This natural process leads to undesirable changes in texture, flavor, and overall quality, shortening the shelf life of numerous food items. Over the years, researchers and food scientists have explored various methods to inhibit this process, with emulsifiers emerging as particularly effective agents. Among these, monoacylglycerols (monoglycerides) and sugar esters have garnered considerable attention for their potent anti-staling properties.

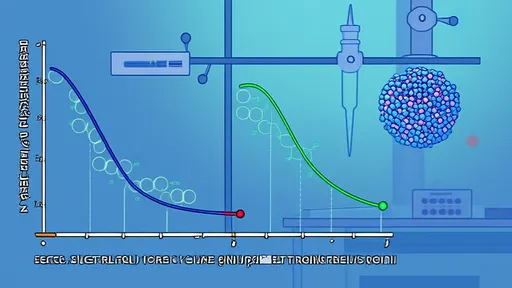

Starch retrogradation occurs when gelatinized starch begins to reassociate and form ordered, crystalline structures upon cooling and storage. This recrystallization, primarily involving the amylose and amylopectin components, results in the firming of crumb, loss of moisture, and the development of a stale taste. The economic implications are substantial, as staling leads to increased food waste and consumer dissatisfaction. Consequently, the development of effective inhibitors has become a priority for manufacturers aiming to extend product freshness and maintain quality.

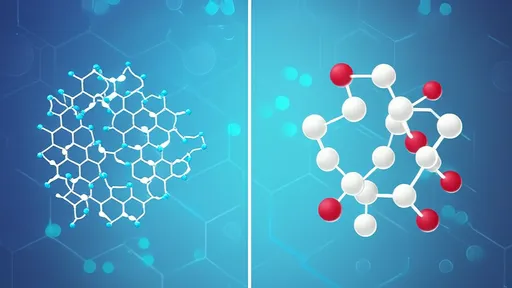

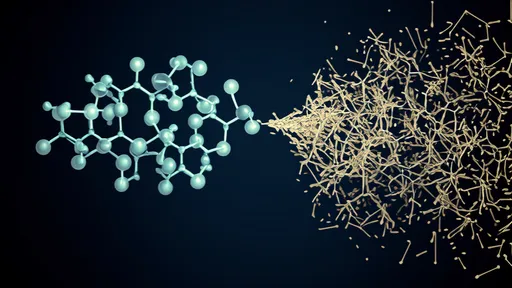

Monoacylglycerols (MG), commonly referred to as monoglycerides, are among the most widely used emulsifiers in the food industry to combat staling. These molecules possess a hydrophilic head and a hydrophobic tail, allowing them to interact effectively with both starch and lipid components in food systems. The primary mechanism by which MG inhibits retrogradation involves complex formation with amylose. During the gelatinization process, when starch granules swell and release amylose, MG molecules can form insoluble complexes with the linear amylose chains. This complexation prevents the amylose from realigning and forming the firm gel network that characterizes staling.

Furthermore, monoacylglycerols interfere with the recrystallization of amylopectin. Although the branched structure of amylopectin retrogrades more slowly than amylose, it is primarily responsible for the long-term staling of products like bread. MG molecules can insert themselves between the branches of amylopectin, hindering the realignment and crystallization processes. This action effectively slows down the firming of the crumb over extended storage periods. The effectiveness of MG depends on factors such as the chain length of the fatty acid component, with saturated fatty acid derivatives like glycerol monostearate being particularly efficacious.

Sugar esters, another class of emulsifiers, also exhibit significant anti-staling properties through similar yet distinct mechanisms. These compounds are formed by esterifying sugars with fatty acids, resulting in molecules with excellent surfactant properties. Sugar esters, such as sucrose esters, can interact with starch components in multiple ways. They are known to form complexes with amylose, much like monoacylglycerols, thereby preventing the formation of a rigid amylose network. However, their smaller molecular size and high hydrophilic-lipophilic balance (HLB) often allow for more uniform distribution within the starch matrix.

The ability of sugar esters to inhibit amylopectin retrogradation is particularly noteworthy. Research suggests that these emulsifiers can effectively plasticize the starch-gluten network, increasing flexibility and reducing the rate of firming. Additionally, sugar esters may enhance water retention within the product. By reducing water migration from starch to gluten or out of the product entirely, they help maintain softness and freshness. This moisture-preserving effect is crucial, as staling is closely associated with the redistribution and loss of water.

When comparing the efficacy of monoacylglycerols and sugar esters, it is evident that both are highly effective, though their performance can vary based on the specific food application and formulation. MG is often praised for its strong complexation with amylose, making it exceptionally good at preventing short-term staling linked to amylose retrogradation. Its widespread use and cost-effectiveness have solidified its position as a industry standard. However, MG has limitations in solubility and distribution, which can sometimes lead to uneven effects.

Sugar esters, on the other hand, offer advantages in terms of versatility and compatibility. They are available in a range of HLB values, allowing for tailored application depending on the system's requirements. High-HLB sugar esters are more hydrophilic and can improve moisture retention, while low-HLB types might better interact with lipid components. Their ability to distribute evenly and interact with both amylose and amylopectin makes them excellent for comprehensive staling inhibition. Moreover, sugar esters are often effective at lower concentrations compared to some traditional emulsifiers.

Synergistic effects between monoacylglycerols and sugar esters have also been observed. In many commercial applications, blends of these emulsifiers are used to leverage the strengths of each. For instance, MG provides robust amylose complexation, while sugar esters enhance moisture retention and interfere with amylopectin recrystallization. This combination approach often yields superior results, extending shelf life more effectively than either emulsifier used alone. The interaction between these compounds and other ingredients, such as proteins and lipids, further modulates their anti-staling effects.

Beyond their direct interaction with starch, both MG and sugar esters influence the broader food matrix. They can improve dough handling, enhance volume, and contribute to a softer initial crumb structure—all factors that indirectly affect the staling rate. For example, a finer and more uniform crumb structure resulting from emulsifier action can reduce the rate of moisture migration and texture hardening. This multifaceted impact underscores the importance of considering the entire formulation when designing anti-staling strategies.

In conclusion, the inhibition of starch retrogradation by monoacylglycerols and sugar esters represents a critical advancement in food preservation technology. Through mechanisms such as complex formation with amylose, interference with amylopectin recrystallization, and improvement of water retention, these emulsifiers effectively delay the staling process. While each has its unique advantages, their combined use often provides the most comprehensive solution. As consumer demand for longer-lasting, high-quality products continues to grow, the role of these emulsifiers will remain indispensable in the food industry's efforts to combat staling and reduce waste.

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025

By /Aug 29, 2025