In the sprawling urban landscapes of modern cities, where infrastructure silently supports daily life, manhole covers represent a critical yet often overlooked component of municipal engineering. Among the various materials employed for these vital access points, ductile iron has emerged as a premier choice, prized for its remarkable durability, strength, and cost-effectiveness. The scientific foundation for its superior performance lies in its unique crystalline microstructure, a subject of extensive study in materials science. This analysis delves into the intricate world of ductile iron's crystal structure, exploring how its formation, composition, and behavior under stress define its role as the backbone of urban utility systems.

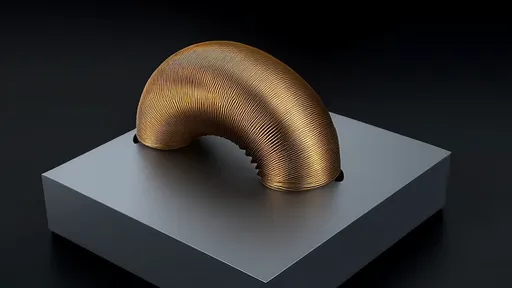

The story of ductile iron, also known as nodular or spheroidal graphite iron, begins with its invention in the mid-20th century, a breakthrough that transformed metallurgy. Unlike its predecessor, gray cast iron, which contains flake graphite that acts as stress concentrators leading to brittleness, ductile iron is characterized by its graphite nodules. These spherical graphite particles are the result of a precise inoculation process, typically involving the addition of magnesium or cerium to the molten iron. This treatment causes the carbon within the alloy to precipitate as spheres rather than flakes during solidification, fundamentally altering the material's mechanical properties and granting it a combination of high strength and impressive ductility.

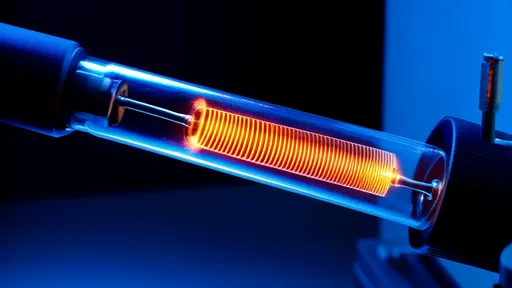

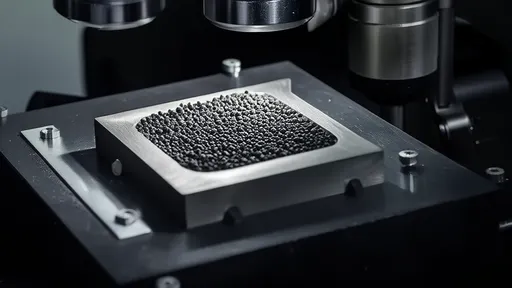

At the heart of ductile iron's performance is its complex multiphase microstructure. The matrix surrounding the graphite nodules can vary based on heat treatment and cooling rates, resulting in different grades of the material. The most common matrix is ferritic, a soft and ductile iron phase, which provides excellent impact resistance. Alternatively, a pearlitic matrix, consisting of alternating layers of ferrite and cementite, offers greater strength and wear resistance but reduced ductility. In some advanced grades, heat treatments can produce austempered ductile iron (ADI), with an ausferrite matrix that provides an exceptional balance of high strength, toughness, and fatigue resistance. This versatility allows engineers to tailor the material precisely to specific application demands, from heavy-traffic roadways to high-pressure water systems.

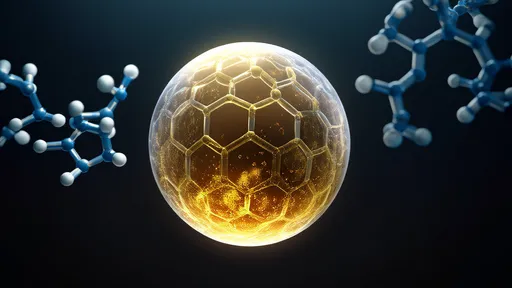

The spherical shape of the graphite nodules is the primary factor conferring ductility. In gray iron, the sharp tips of graphite flakes act as inherent cracks, easily propagating under tensile stress and causing catastrophic brittle failure. In contrast, the rounded nodules in ductile iron blunt the progression of cracks. When stress is applied, the relatively soft graphite spheres can absorb energy by deforming slightly, while the surrounding metal matrix stretches and redistributes the load. This mechanism allows the material to undergo significant plastic deformation before fracture, a property crucial for components that must withstand impact loads, such as a heavy truck passing over a manhole cover at speed.

The formation of this beneficial microstructure is not a guaranteed outcome but is the result of meticulous control over the casting process. The critical step is the inoculation treatment, where the nodulizing agent is added. The effectiveness of this treatment depends on factors like the temperature of the molten metal, the purity of the iron (particularly low levels of deleterious elements like sulfur), and the timing of the pour. Rapid cooling after casting can also influence the matrix structure, promoting the formation of harder phases like pearlite. Foundries must therefore employ rigorous process controls and quality checks, often using metallographic analysis to confirm the nodularity—the percentage of graphite that has formed into spheres—ensuring it meets the high standards required for critical infrastructure components.

Beyond its mechanical prowess, the crystalline structure of ductile iron grants it outstanding corrosion resistance, a vital attribute for manhole covers constantly exposed to moisture, road salts, and chemical runoff. The graphite nodules, though carbon, are encapsulated within the iron matrix, limiting their exposure. Furthermore, the metal itself can form a protective layer of rust that inhibits further degradation. This passive layer, combined with the material's inherent density and lack of continuous porosity, makes it highly resilient against the elements, ensuring a long service life even in harsh environments and reducing the frequency and cost of replacement for municipal authorities.

When subjected to the cyclical loading of urban traffic, the fatigue performance of ductile iron is exemplary. The nodules, once again, play a key role. They hinder the initiation and growth of fatigue cracks by homogenizing stress distribution throughout the material. In high-cycle fatigue scenarios, where a cover might experience millions of stress cycles over its lifetime, this resistance to crack propagation is essential for maintaining structural integrity. This makes ductile iron not just strong, but reliably durable over decades of service, a key economic and safety consideration for public works projects where failure is not an option.

The advantages of ductile iron extend into the realms of sustainability and economics. Its longevity means fewer replacements and lower long-term maintenance costs. Furthermore, as a cast metal, it is highly recyclable. At the end of its long life, a ductile iron manhole cover can be melted down and recast into a new product with minimal degradation in quality, supporting circular economy principles within urban infrastructure management. This recyclability, coupled with the material's durability, presents a compelling life-cycle argument for its continued and expanded use in smart city development around the globe.

In conclusion, the unassuming manhole cover is a testament to sophisticated materials engineering. The superior serviceability of ductile iron is not a happy accident but a direct consequence of its deliberately engineered spheroidal graphite microstructure. This structure transforms a inherently brittle material into one that is strong, ductile, fatigue-resistant, and durable. As cities continue to grow and evolve, the silent reliability of these ductile iron components will remain a foundational element of safe and functional urban infrastructure, a perfect marriage of materials science and practical engineering that quite literally supports the world above.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025