In the intricate world of wood chemistry, few processes are as consequential yet as overlooked as the release of aldehydes during lignin decomposition. This phenomenon, which lies at the intersection of industrial processing and environmental science, has long been a subject of niche academic interest. However, recent findings detailed in the groundbreaking report New Book Aldehyde Release: Chemical Kinetics of Lignin Decomposition have thrust this topic into the scientific spotlight, revealing complexities that challenge long-held assumptions and open new avenues for research and application.

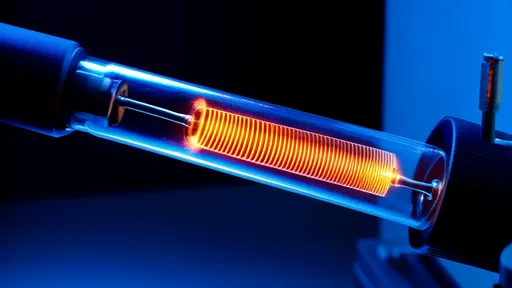

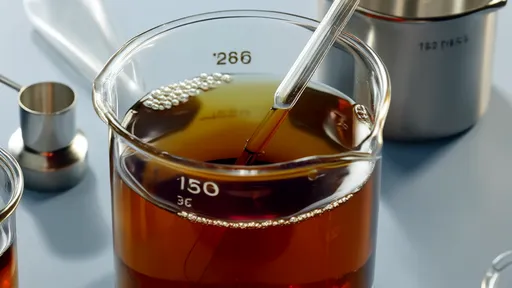

The study meticulously documents how aldehydes—volatile organic compounds with significant implications for air quality and human health—are not merely passive byproducts but active indicators of the lignin breakdown process. Through painstaking experimentation under varied conditions of temperature, pH, and catalytic presence, the research team has mapped the kinetic pathways of these reactions with unprecedented precision. What emerges is a picture far more dynamic than previously imagined, where subtle changes in environmental parameters can dramatically alter both the quantity and type of aldehydes released.

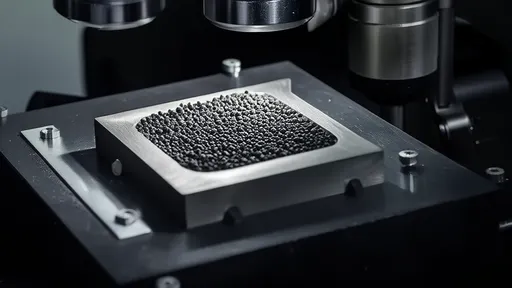

Central to the report's findings is the revelation that the decomposition is not a single, monolithic reaction but a cascade of competing pathways. The traditional view of lignin breaking down in a relatively linear fashion has been supplanted by a model of simultaneous depolymerization and condensation reactions, each with its own kinetic profile and aldehyde yield. This complexity explains why previous attempts to model or control aldehyde release have often fallen short, lacking the granularity to account for these interdependent processes.

Perhaps the most striking insight concerns the role of water. While moisture has always been known to influence wood chemistry, the new data illustrate its function as both a medium and a reactant in aldehyde formation. Hydrolytic cleavage of ether bonds in lignin, previously considered a secondary pathway, is shown to be a primary driver of formaldehyde release under certain conditions. This has profound implications for industries like construction and furniture manufacturing, where engineered wood products, often in humid environments, can become significant sources of indoor air pollutants.

The kinetics of these reactions, detailed with mathematical rigor in the report, reveal activation energies and rate constants that vary significantly across different lignin subunits. Syringyl units, for instance, demonstrate a higher propensity for vanillin formation under oxidative conditions, while guaiacyl units tend toward coniferaldehyde production. This subunit-specific behavior means that the botanical source of the lignin—hardwood versus softwood—becomes a critical factor in predicting aldehyde emissions, a nuance largely absent from earlier models.

Beyond the laboratory, the implications of these findings are vast and immediate. For the pulp and paper industry, which has long grappled with controlling odorous and hazardous emissions, the kinetic models offer a roadmap for optimizing processes to minimize aldehyde release without sacrificing efficiency. The data suggest that relatively minor adjustments in digester temperature profiles or the timing of oxidant introduction could yield significant reductions in emissions, potentially saving millions in mitigation costs.

In the realm of environmental science, the report provides a missing piece in the puzzle of biogenic volatile organic compound (BVOC) emissions. Forests, particularly those undergoing natural decay or managed harvesting, are known sources of atmospheric aldehydes, but models have struggled to accurately quantify these fluxes. The kinetic parameters established in this work allow for more precise predictions of how different tree species, under various climatic conditions, contribute to regional air chemistry and, consequently, to issues like tropospheric ozone formation.

The health and safety dimensions cannot be overstated. Formaldehyde, acetaldehyde, and other aldehydes released from wood products are classified as carcinogens or irritants. Regulatory bodies have increasingly tightened exposure limits, placing pressure on manufacturers to better understand and control emissions. This research empowers them to do so from a position of fundamental understanding rather than trial and error, potentially accelerating the development of safer materials and compliant processes.

Looking forward, the authors posit that this kinetic framework could become the foundation for a new generation of green wood processing technologies. By harnessing the precise understanding of reaction pathways, it might be possible to steer decomposition toward less harmful aldehydes or even capture and utilize these compounds as chemical feedstocks, transforming a waste problem into a value stream. The concept of a biorefinery that intentionally produces aldehydes for the fragrance, flavor, or pharmaceutical industries moves from theoretical to plausible.

Inevitably, the work also highlights gaps in our knowledge, particularly regarding the synergistic effects of multiple variables acting in concert. The report calls for a concerted interdisciplinary effort, combining advanced analytical chemistry, computational modeling, and process engineering to build upon this kinetic foundation. It is a clarion call for a more holistic approach to understanding wood, not just as a structural material but as a complex chemical ecosystem.

In conclusion, New Book Aldehyde Release: Chemical Kinetics of Lignin Decomposition does more than just present data; it redefines a field. It transitions the study of lignin decomposition from a descriptive science to a predictive one, offering tools and insights that resonate across industries and disciplines. In doing so, it underscores a timeless scientific truth: that deep inquiry into the fundamental processes of nature, no matter how specialized they may seem, invariably yields knowledge with the power to shape technology, protect health, and steward our environment.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025