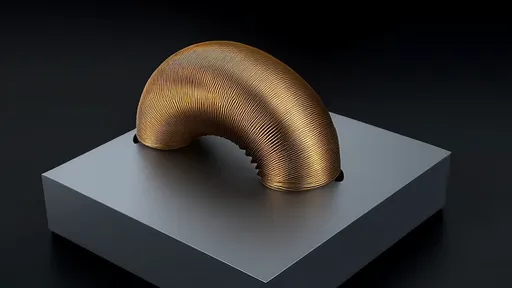

In the realm of materials science and engineering, the study of stress-strain curves for various alloys remains a cornerstone of understanding mechanical behavior under load. Among these materials, brass alloys have garnered significant attention due to their unique combination of properties, including excellent machinability, corrosion resistance, and aesthetic appeal. The book Bridge Lock Materials Mechanics: Stress-Strain Curves of Brass Alloys delves deeply into this subject, offering a comprehensive exploration that bridges theoretical principles with practical applications. This work not only serves as an academic reference but also as a vital resource for engineers and designers working in fields ranging from construction to consumer electronics.

The stress-strain curve is a fundamental graphical representation that illustrates how a material deforms under applied stress. For brass alloys, this curve is particularly intriguing due to the material's composition, which typically includes copper and zinc in varying proportions. The book begins by laying a solid foundation in the basics of material mechanics, ensuring that readers, whether students or seasoned professionals, can grasp the nuances of how brass behaves under different conditions. It emphasizes the importance of understanding elastic and plastic deformation regions, yield points, and ultimate tensile strength, all of which are critical for predicting failure and ensuring safety in engineering designs.

One of the key highlights of Bridge Lock Materials Mechanics is its detailed analysis of how different brass compositions affect the stress-strain relationship. For instance, alpha brasses, with zinc content up to 35%, exhibit superior cold-working properties and a distinct curve characterized by a pronounced yield point and gradual strain hardening. In contrast, beta brasses, with higher zinc content, show different mechanical behaviors, including reduced ductility but increased strength. The book provides exhaustive data and curves for various brass types, supported by experimental results and microstructural analysis, helping readers visualize and comprehend these differences effectively.

Beyond mere theory, the publication excels in connecting laboratory findings to real-world applications. Brass alloys are ubiquitous in bridge locks, fasteners, and architectural elements where mechanical integrity is paramount. The authors discuss case studies where understanding the stress-strain curve has led to improved product designs and failure analyses. For example, in bridge lock mechanisms, the ability of brass to undergo plastic deformation without fracturing is a double-edged sword; it allows for energy absorption but requires careful calculation to avoid excessive deformation. The book offers practical guidelines on selecting the right brass alloy based on its stress-strain characteristics to meet specific engineering demands.

Another compelling aspect covered is the influence of external factors such as temperature, strain rate, and manufacturing processes on the stress-strain curve of brass. Elevated temperatures can reduce yield strength and increase ductility, altering the curve significantly, which is crucial for applications in varying environmental conditions. Similarly, the rate at which stress is applied—whether suddenly or gradually—can impact the material's response, a consideration vital for dynamic loads in machinery or impact scenarios. The book includes chapters dedicated to these variables, complete with graphs and empirical models that predict behavior under non-standard conditions.

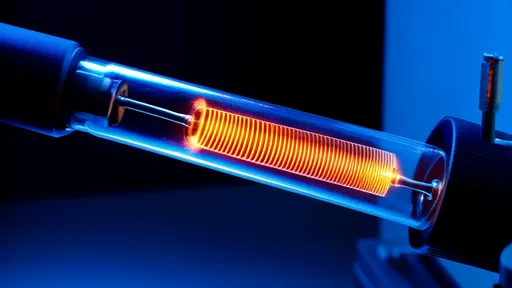

The authors also address modern advancements in material testing technologies that have refined our understanding of brass mechanics. Techniques like digital image correlation (DIC) and high-resolution strain gauges allow for more precise mapping of deformation, revealing subtleties in the stress-strain curve that were previously undetectable. These innovations are discussed in the context of brass alloys, showing how they contribute to more accurate simulations and finite element analyses (FEA) in engineering software. This section underscores the evolving nature of material science and the continuous improvement in predictive accuracy for mechanical performance.

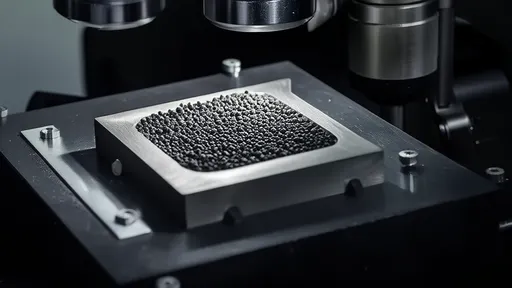

In its concluding sections, Bridge Lock Materials Mechanics looks toward the future, exploring emerging trends such as the development of new brass composites and nano-structured alloys that promise enhanced properties. The stress-strain curves of these advanced materials are compared with traditional brasses, highlighting potential benefits like higher strength-to-weight ratios or improved fatigue resistance. This forward-thinking approach not only informs current practices but also inspires innovation in material design and application.

Overall, this work stands as an authoritative and meticulously detailed reference on the stress-strain behavior of brass alloys. Its blend of theoretical depth, practical insights, and attention to contemporary advancements makes it an invaluable asset for anyone involved in material selection, mechanical design, or failure analysis. By demystifying the complexities of brass mechanics through clear explanations and rich data, the book empowers engineers to make informed decisions that enhance safety, efficiency, and performance in their projects.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025